3-D printing is a quite exciting technology that has come to light in recent years. The process involves a nozzle much like in a regular inkjet printer that layers material upon material to build up a 3D structure. The printer receives this data from a computer designed file that maps out where the printer should add material. Combine this with filler material that serves to hold everything in its final upright position, and the final product is born, after setting and clearing off the filler. This process has been used to make many different things, from simple objects like phone cases and luggage tags to complex scaffolds used to hold cells for tissue engineering, or as in this post, specific implants for dogs and other animals. The usual types of orthopedic implants that have somewhat of a cookie cutter size distribution for humans do not always fit in dogs or other animals. So, 3-D printing has been employed to create implants used to repair and replace bones in veterinary situations.

The most prominent veterinary application for 3-D printed implants is dogs. This is due to their slight differences in body type, even within breeds, that can make finding a pre-sized and pre-made implant difficult to find. One such example of this is a dachshund, named Patches, that received a custom made skull implant after other implants were found to be ineffective or dangerous to her long term health. Patches had a brain tumor, one that grew to a very large size and began encroaching on her eyes. The tumor was successfully removed, but the process involved the removal of large portions of her skull, leaving her brain unprotected. If a preexisting implant were tried, the way it would fit would leave her head vulnerable to an impact, making the implant quite pointless. A 3-D printed implant was made, and old Patches made a full recovery.

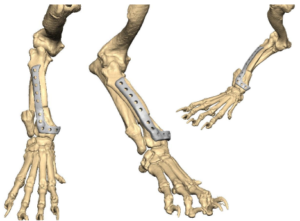

The process involves taking a CT scan of the area in question and gaining an understanding as to the layout of the area. This allows designers to make a 3-D model of the implant using a computer, and that model can be printed out using a 3-D printer. In the case of implants, titanium is usually used due to its biocompatibility and great mechanical strength. The implants can be used for surgery and repair, or an array of other applications, even studying the cranial activities of primates. In any case, these exciting new developments in 3-D printing are leading to advancements in the medical and biological fields. So, the next time you fire up you 3-D printer to make a cool-looking hood ornament, know that the same technology is at work, saving lives and giving scientists new knowledge about animals they previously had no good way of studying.

Featured Image by huoadg5888 from Pixabay