When one imagines the wonders of the natural world, the spider is not the first organism that comes to mind. However, possibly the most hated beings in all creation produce one of nature’s marvels: spider silk.

Properties

Spider silk has a number of properties that make it such an impressive material. First, spider silk is incredibly strong and tough. Spider silk is stronger than steel, and its toughness, or ability to absorb energy, is nearly three times that of Kevlar. And spider silk weighs less than both materials. These three properties alone would qualify spider silk as a super-material. The structural and ballistic industries stand to be disrupted by spider silk materials. For example, because spider silk can absorb energy better than Kevlar and is more lightweight, spider silk would be an excellent material for military and civilian self defense applications.

Spider silk also has an elasticity similar to that of human tendons while exhibiting a near perfect resistance to fatigue. Hennecke et al. show that spider silk has a similar stress-strain curve to that of a human tendon, and both materials have a memory which allows them to recover their form after loading. Tendons are constantly being loaded and unloaded throughout their life. Finding adequate materials for artificial tendons is particularly difficult, because most materials begin to lose their properties in cyclic loading, leading to a defined and small life time for the number of cycles tendons are forced through. But spider silk does not appear to lose its strength or elasticity even after high numbers of cycles.

In addition to these physical properties, spider silk also has been found to be both antiseptic as well as biocompatible. Spider silk has been used for medicine since ancient times due to its antiseptic properties, and for this reason, as well as its strength and toughness, spider silk is an excellent component in salves and bandages. Artificial tendons are prone to infection, and so spider silk’s antiseptic property is another reason why it is an ideal material for this application. Because spider silk is also biocompatible, as well as tough, it is a viable material for organ repair.

Harvesting Silk

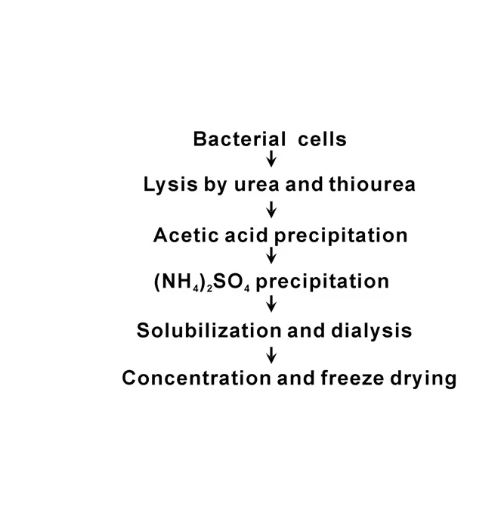

Unfortunately, spiders can’t be farmed en masse like other silk-producing insects, such as silkworms, because spiders happen to be cannibals. Thus, natural spider silk remains incredibly expensive and time consuming to harvest. To overcome this problem, scientists have tried to reproduce spider silk in various ways. Attempts to manufacture the protein in bacterial cells were largely unsuccessful because of the size of the gene and complexity of the codon structure. Scientists then tried a number of eukaryotic hosts to express the spider silk protein. Expression in yeast cells, plant cells and goat’s milk were tried, but all failed to produce a viable protein that survived the purification process. Silk-producing insects, like silk worms, had the most success expressing the spider silk gene, but this method was still inefficient for large scale production. The difficulties in large scale production are demonstrated by the complicated purification process used by Xia et al. to purify spider silk proteins harvested from bacteria cells, shown to the left. The above methods of protein production are inefficient and unreliable, but the real problem facing scientists is not the expression of the protein but weaving the protein into silk. Artificially woven spider silk proteins have exhibited large diameter fibers and so worse mechanical properties.

Despite the failures to reproduce the properties of spider silk exactly, companies such as Kraig Biocraft, have patented a number of products made from artificial spider silk and are marketing towards textile, medical, and ballistic markets. Kraig Biocraft estimates that the market for technical fibers, such as their artificial spider silk, is well over a hundred billion dollars. With human ingenuity, and money like that at stake, it is only a matter of time before bioengineers can produce a material in quantity with the properties of natural spider silk.