The following examples are representative (but not exhaustive) of the types of industry sponsored project opportunities available in the MEng program.

City of Holland, Michigan Board of Public Works Seawall Replacement & Site Development

Sponsor: Abonmarche Consultants, Inc.

Mentors: Martin Rivas

Students: Michael Tuohy, Esenia Delgadillo, Molly Marino, and Paul Quinn (MEng)

Project Description:

The project site is located in Holland, MI, and is on top of a decommissioned coal power plant. The site is classified as a brownfield, and the Holland BPW owns the parcel. Since the decommissioning in 2023, the site has remained vacant and emergent wetlands have appeared within the site. Currently, plans are in place to redevelop the site into a port facility to accommodate the loading/unloading of aggregate piles from Great Lakes’ freighters. The student team, with the support of Martin Rivas from Abonmarche, is tasked with designing a new 1,100 foot long anchored steel sheet pile seawall to replace the existing seawall system, which was determined to be insufficient due to corrosion, concrete spalling, and design life exceedance. The team is also tasked with preparing the site for redevelopment by obtaining necessary permits from the Michigan Department of Environmental Great Lakes & Energy (EGLE) and U.S. Army Corps of Engineers (USACE).

The goal is to prepare existing and proposed construction drawings of the site which will include grading plans, wall alignments, returns, and connections details, backfill details, wall anchor layout, toe stone details, and further site needs.

Coyle Hall

Sponsor: Bulley & Andrews

Mentors: Jackson Kamp and Collins Udeh

Students: Joel Brink (MEng), Pedro Sampaio (MEng), and Ben Fraser

Project Description:

The motive behind this capstone project is to give our team practical experience in construction management through direct involvement with an active institutional project. By working with Bulley & Andrews on the Men’s Dorm at the University of Notre Dame, the team is gaining insight into the workflows, decision making, and coordination required for complex construction efforts. While many initial tasks such as takeoffs, sequencing, and estimating were completed by the contractor, the team’s focus is on monitoring progress, managing changes, and identifying opportunities to improve efficiency and constructability. The team’s goal is to deepen the understanding of project execution and provide meaningful input that supports Bulley & Andrews’ current and future work on campus.

To support this effort, the team is using industry standard construction management software and documentation tools to stay organized and effective. The team relies on Procore and Bluebeam to review, annotate, and track drawings, specifications, and reports. This project provides an opportunity to apply what is learned in the classroom to a real world construction setting while continuing to develop the technical, organizational, and communication skills to perform effectively in the construction industry.

27 Story Reinforced Concrete Apartment Building

Sponsor: Severud

Mentors: Jack Gainey and Ed DePaolo

Students: Quinn Akerman (MEng) and Matthew Teague (MEng)

Project Description:

For this project the student team is being tasked with designing the structural system for a 27 story reinforced concrete apartment/commercial building. In the design of the 293 foot building going up from the fourth floor the part of the building will sit on a cantilever due to an existing house near the building forcing the first three floors to be smaller than the other twenty four. The building’s main structure will consist of concrete shear walls in the core of the building, concrete columns, and concrete slabs. Using provided architectural drawings the team will ultimately deliver a 90% plan set of the building’s structural system. This will entail the calculation of the loading on the building using the ASCE 7-22 code and the use of SAP2000 to model the building and develop the lateral loading values. The team will then design the concrete sections and foundations in the building to carry the determined loading and match the architectural drawings as well as possible using the relevant AISC 16th edition and ACI318-19 codes when necessary. Much of this work will be done using Excel but it will also be checked with hand calculations. Finally using the designed elements the team will draft a 90% plan set of the building’s structure using Revit.

93 Acre Industrial Bridge Design

Sponsor: Westwood

Mentors: Eric Herbert, Dominique Madrid

Students: Patrick Dampf, Brian Leung (MEng), Liszeth Rodriguez (MEng)

Project Description:

For this project the student team is designing a reinforced concrete vehicular two span bridge located in Sanger, Texas. The intent of this bridge is to connect two roadways divided by the Ranger Branch Creek. The bridge design will be done using codes and specifications outlined in TxDOT and AASHTO. The students will be using software such as AutoCad, BlueBeam, and Excel to create drawings, calculate load cases, and conduct an economical analysis of our bridge. In addition to technical drawings and calculations, the team will also be creating a technical report that will outline the basis of the bridge design. Included in this report will be the basic geometry of our bridge, the standards that used in the design, and any assumptions that were made in the design.

County Line Landfill Modification

Sponsor: Weaver Consultants Group and Republic Services

Mentors: Jeff Neville (WCC) and Joe Benco and Megan Crowley (RS)

Students: Grace Combs, Theodore Doran (MEng), Sarah Oliva, and Julia Safford (MEng)

Project Description:

The County Line Landfill, owned and operated by Republic Services, is submitting a Minor Modification Permit Application prepared by Weaver Consultants Group. The application requests approval for a vertical expansion and a revised synthetic turf final cover system. The proposed modification includes adjusting the permitted top-of-waste grades to increase overall site capacity by less than 500,000 cubic yards, consistent with the criteria for a minor modification. Students, acting as Weaver Consultants Group, will prepare revisions to the final grading plan to reflect the updated grades and cover design. The existing soil and topsoil cover layers, totaling approximately 8.5 feet, will be replaced with a geosynthetic artificial turf system designed to improve performance and long-term durability while reducing maintenance costs. A detailed cost comparison between the proposed synthetic turf system and the traditional soil cover will demonstrate the operational and economic advantages of the revised design.

In addition to grading and cover system updates, students will revise the stormwater management plan to incorporate updated stormwater runoff and volume calculations based on the new final grades and surface conditions. Supporting engineering analyses include updated HydroCAD and HELP model calculations, and modifications to the closure and post-closure care plans to ensure regulatory compliance and long-term performance. Plan-view drawings will be prepared in Civil 3D to illustrate the revised final grades, stormwater management features, and cover system configuration. These updates will be submitted jointly by Republic Services and Weaver Consultants Group as part of the County Line Landfill’s Minor Modification Permit Application for review and approval by the Indiana Department of Environmental Management (IDEM). All deliverables will be aligned with IDEM 329 IAC Article 10.

Jersey City Residential Building

Sponsor: Severud Associates

Mentors: Edward DePaola and Jack Gainey

Students: Ella Burns (MEng), Joe Cisar (MEng), and Emma Quinn

Project Description:

The goal of this project is to design a 27 story reinforced concrete building in Jersey City, NJ. The building is 293 feet tall with a bulkhead roof, as shown in the figure below. It consists of a shear wall core to take the majority of the lateral load and columns to take gravity loads. The columns and slabs act as moment frames. The third floor of the building has a cantilever in the southeast corner due to an adjacent house refusing to sell. Floors 4 through 27 are identical in architectural plans. The building will be mainly residential, with retail space on the first and second floors and office space on the third floor.

For this project, the student team will use the architectural drawings to get started on their design. They will perform load calculations according to the New Jersey Building Code and ASCE 7-16 standards. The team will use SAP2000 to model the lateral system and RAM Concept to model the gravity loads. Each model will be checked with hand calculations. The students will use the results from these calculations and analyses to design the foundation, columns, slabs, shear walls, and beams of the building.

US-6 Bridge Replacement over Cedar Creek – Waterloo, Indiana

Sponsor: American Structurepoint

Mentor: DJ Bosse and Thomas McNicholas

Students: Elle Akerman (MEng), Luke Linder (MEng), Diego Gonzalez (MEng), and Martin Rivas, P.E. (MEng)

Project Description:

Our MEng capstone group was tasked to study a bridge replacement project originally designed/engineered by our mentor, American Structurepoint, Inc. (ASI). In 2023, an aging bridge crossing over Cedar Creek along US-6, located immediately East of Waterloo, Indiana, was fully replaced. The original bridge was built in 1926 as a 2-span, simple concrete girder structure with a T-shaped cross-section. Since the original construction, three major rehabilitation projects occurred with subsequent improvements being: (1) widening and superstructure replacement in 1950, (2) rigid deck overlay and new railings in 1991, (3) patching of deck and substructure, minor girder patching, and crack sealing in 2017.

Tasks completed by ASI (which our capstone group must follow and recreate during the 2024-2025 school year) include hydraulic/hydrologic modeling using HEC-RAS software for regulatory permitting procedures, maintenance of traffic planning for construction phasing operations, bridge design progress drawings using AutoCAD Civil 3D (with QAQC by INDOT), and compilation of technical calculations. This work is completed by the Notre Dame team between weekly meetings with ASI on Thursdays at 11:00am-12:00pm via Microsoft Teams, with Elle Akerman and Martin Rivas, P.E., specializing in the hydraulics components and Luke Linder and Deigo Gonzalez specializing in the physical bridge components in these initial stages of design.

For preliminary design, ASI worked with a land surveying sub-consultant to capture the topographic contours of the project site, to retrace existing Right-Of-Way boundaries, and also worked with a geotechnical engineering sub-consultant to gather soil borings, and ascertain geotechnical recommendations for understanding how to design the new bridge pier foundations given the local soil conditions. As-needed utility coordination was performed by ASI, in addition to the preparation of bid drawings, bid documents, technical specifications, bid award procedures, and final contract document negotiations, and ASI conducted construction administration services throughout construction (i.e., materials testing, technical submittal reviews, and necessary inspection reports for general project oversight); these tasks are outside of the scope of our capstone group project but are supplemental information provided by ASI to our group.

Merchants Bridge

Sponsor: The Walsh Group (in collaboration with Collins Engineering, Doka, and Genesis Structures)

Mentors: Mike O’Donnell, Adolfo Mora, and Daniel Sieve

Students: Brittany Alvarez (MEng), Adam Reinart (MEng), Brigid Garvey(MEng), and Macy Eglinton Manner

Project Goals: (1) Retrofit design of Merchants Bridge, (2) Replaced 3 truss spans & pier encasements, (3) Returned service to both tracks across the bridge, (4) Doubled the bridge’s capacity, (5) Increased track centers to 15 feet, (6) Reduced necessary bridge maintenance

Location: Over the Mississippi River – connecting St. Louis, MO to Venice, IL

Owner: Terminal Railroad Association (TRRA) of St. Louis

Architect: TranSystems / Burns & McDonnell

Contract Value: $180,000,000

Contract Awarded: 2018

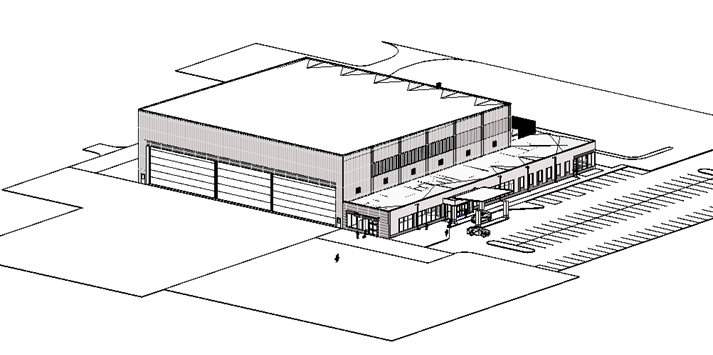

Structural system for an airport hanger

Sponsor: Thornton Tomasetti

Mentors: Elena Poludnitcyna, Barry Lee, and Joe Porada

Students: Rory McCarthy (MEng), Matthew Hoffman (MEng), Liz Chen, and Emmett Christenson

Project Description:

In collaboration with Thornton Tomasetti, our team is designing the structural system for an airport hangar located in Cleveland. This project is meant to highlight and exercise our design skills in a “real world” situation. The main constraint of the building is the design of a structural system that can support the 180’ roof span without columns to allow for easy maneuverability of planes in the hangar. Additionally, the foundation and slab systems must adequately support the weight of several airplanes. Finally, a unique component of this project is a blast analysis of the structure, and verifying the design will be sufficient to withstand the imposed loads. Beyond these constraints, we are encouraged to exercise our creativity throughout the structural design process. We were tasked with researching several potential structural system configurations; developing lateral and gravity loads using ASCE-7, the Ohio Building Code, and the Cleveland Building Code; analyzing possible truss configurations using SAP2000; and designing the slab on grade. Moving forward, we will begin to design the lateral system, combine the lateral and gravity systems in a Revit model, develop blast loads, and further analyze the structure for gravity, lateral, and blast loads in SAP2000.

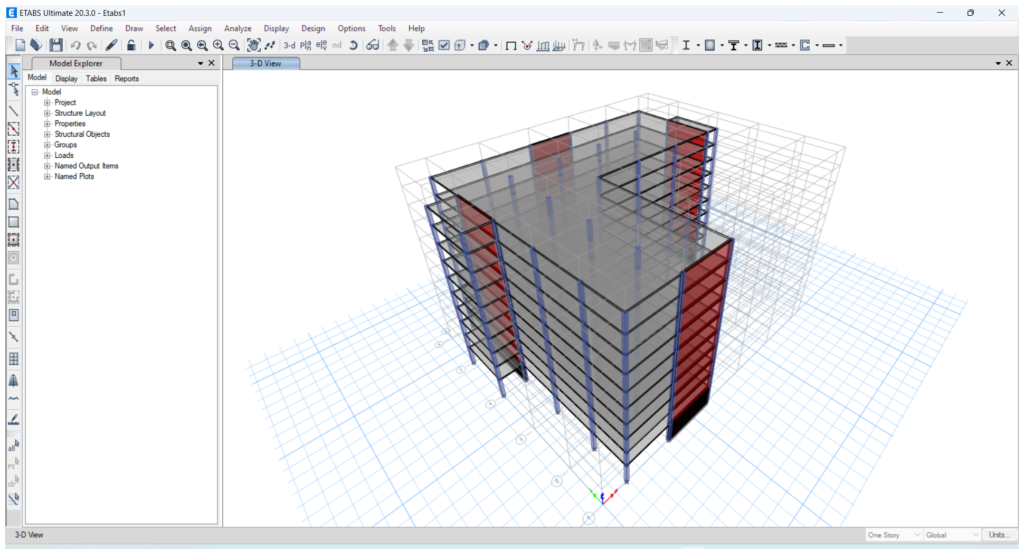

Project: Analysis and Design of 11-story Concrete Frame Building

Industry Sponsor: Schaefer

Course(s): CE 60274 – Advanced Concrete and Prestressed Concrete Design

Students: Mua’yyed Malabeh (MEng) and Henrique Martins

The team was mentored through the design process of an 11-story cast-in-place reinforced concrete building with post-tensioned slabs. A professional engineer from Schaefer, Matthew Horne. P.E. volunteered his time to the graduate students. The project started with the design criteria for calculating the vertical and lateral loads on the building using ASCE 7-16 design code. The design process was initiated by calculating the preliminary column loads, column sizes, and gravity foundation design using hand calculations and Excel. The lateral system (shear wall) finite element analysis was completed by modeling the entire structure using ETABS, and design was completed by utilizing ETABS built-in shear wall design module. Post-tensioned slab design was completed next and performed using RAM-Concept. Using the unbalanced slab-to-column moments calculated by RAM Concept in combination with the previously calculated axial loads, the final column design was completed in spColumn. Finally, a set of conceptual structural drawings were created along with final column and footing schedules.

Project: Youth Service Bureau & South Bend Thrive Development Project Site Design

Industry sponsor: City of South Bend

Mentors: Charlotte Brach and Eric Horvath

Course(s): CE 67600 – Special Studies: MEng Capstone

Students: Bethel Aninyei (MEng) and Yiqiao Qin

This design project works as part of the Youth Service Bureau and South Bend Thrive Development Project for the City of South Bend. In this project, we are planning to utilize a currently underdeveloped 16-acre site which is 3 miles to the southeast of the University of Notre Dame campus in South Bend. The site is marked by the Sorin Park to the north, the Mckinley Ave. to the south, the U-Haul Neighborhood Dealer Building to the east, and the Preston Dr. residences to the west. This site will consist of residential and commercial lots, with a YSB community center, and low income residential housing. In order to help construct the site, this senior project will come up with the layout plans for the residential and commercial lots in this area and give further suggestions on some aspects of the infrastructures such as sewer system design. The references of this project include the standards from both the City of South Bend and the YSB project. We will be using ArcGIS and AutoCad as the engineering tools in our progress.

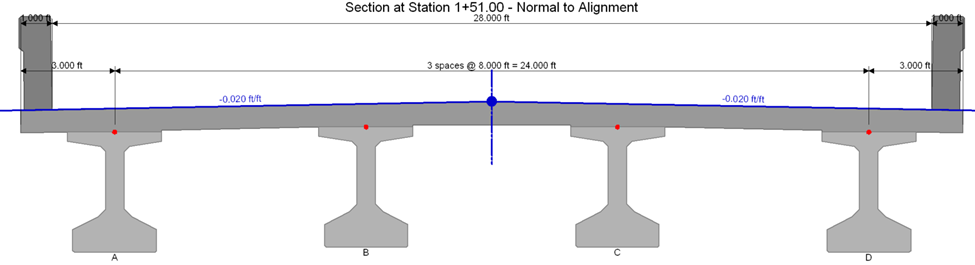

Project: TxDOT Prestressed Girder Bridge Design

Industry Sponsor: Kiewit Infrastructure Engineering

Course(s): CE 67600 – Special Studies: Prestressed Concrete Design

Students: Karla La Torre Alvarez (MEng) and Will Tjaden

The team was mentored through the design process of precast prestressed (PCPS) concrete I-girders that were part of a representative freeway bridge in Texas. Two engineers from Kiewit Infrastructure Engineers, Eric Herbert S.E. P.E. & Samuel Hess P.E., graciously volunteered their time to the graduate students. The girders were designed using the Texas Department of Transportation (TxDOT) Bridge Design Manual and the AASHTO LRFD Bridge Design Manual. The design process included generating dead and live loads for both interior and exterior girders, calculating necessary live load distribution factors to distribute the live loads per girder, and calculating losses were calculated based on the TxDOT state specific equations which investigated both long and short conditions. Finally, a set of conceptual drawings were created that displayed the bridge layout, typical I-girder section details including reinforcement details and an elevation view of the prestressed girder. The team utilized a PCPS girder design software called PGSuper developed by the Washington Department of Transportation and TxDOT for the streamlined design of PCPS bridges. With every output from the software considered in the design, hand calculations were performed to quality assure the proposed design. Deliverables included detailed calculations for the design process and drawings that abide to TxDOT Standards.

Project: Affordable Housing Development in Mishawaka, Indiana

Industry Sponsor: Housing for Humanity in collaboration with the Notre Dame School of Architecture and multiple regional design and development firms

Course(s): Fall Break Special Activity with Professor Phil Barutha

Students: Hany Alrahahleh (MEng), Karla La Torre Alvarez (MEng), Mua’yyed Malabeh (MEng), and John Anyanwu (MEng)

During the Fall Break, a group of MEng students led the site-civil design efforts in a “Charrette Project” at the University of Notre Dame in partnership with Habitat for Humanity. The goal of the project was to create more affordable housing in the local community of Mishawaka. The team used engineering principles to evaluate and address the various challenges common with residential development projects, including site runoff and storage as well as transportation accessibility.

Project: Virginia Tech Trellis Structure

Industry Sponsor: Gannett Fleming

Course(s): CE 40701 & CE 40702 – Principles of Practice & Capstone Design

Students: Elena Poludnitcyna (MEng), Elizabeth DePaola, and Gregorio Sanz do Santamaria

Virginia Tech is designing a new mixed use development for its campus near the Potomac river in Alexandria, VA. The new development will include residential, office, retail, and educational facilities, and will replace an old retail development that previously existed in the area, which will generate a greater flow of wastewater. Therefore, per city requirements, the old wastewater will be replaced by a new pump station facility. The trellis structure that’s being designed will stand next to the pump station, integrating the structures into the new park and educational walkway. Our team, along with Gannett Fleming, will be focusing on the design of the structural elements of the trellis, particularly beams, columns, footings and battens. We also are going to design the frame connections using TEKLA Structures. During the Fall semester our team will focus on calculating the environmental loads acting on the trellis (gravity, seismic, ice, wind, wind on ice, etc.), modelling the trellis on SAP200, looking at load combinations to design the member sizes, and eventually design the foundation for the structure. Throughout the Spring semester, we will focus on designing the connections and going into the details of the overall trellis structure. We will also be using TEKLA and Revit for our design and cost estimation, as well as drawing our design in AutoCAD. We will be referencing IBC 2018, ASCE 7-16, and the Aluminum Design Manual2010 to perform our calculations throughout these two semesters. Along with all of these references and software, our team will be hand calculating everything. Our team plans on accomplishing all of these goals and if we have time, we may also begin working on shop drawings for our structure, cost estimation, and statement of special inspections.