ALS (Amyotrophic Lateral Sclerosis, a.k.a. Lou Gehrig’s disease) is is a rare but serious neurodegenerative condition that gradually causes muscle weakness and loss of control, eventually impacting the ability to move, speak, and breathe. It affects around 20,000-30,000 people in the U.S. at any time, with most cases diagnosed between ages 40 and 70.

Current ALS treatments are limited by a focus on symptom management and lack of understanding of the disease’s cause, but new technologies like 3D printing can offer exciting opportunities for innovation, such as custom prosthetics, artificial muscles, tissue engineering, and personalized medicine, which could significantly improve patient outcomes.

Revolutionizing Muscle Repair with 3D Printing

3D printing is transforming medicine by enabling scientists to create complex structures layer by layer, using bio-compatible materials. As demonstrated by De Pascali et al., this technology allows for the precise fabrication of muscle-like structures that can closely mimic the function and flexibility of natural tissues. These artificial muscles aren’t one-size-fits-all; the customization enabled by 3D printing ensures that each muscle can be tailored to meet a patient’s unique needs, from size to specific functionality. This level of precision offers hope for developing personalized treatments, especially for conditions like ALS, where damaged muscle function needs targeted support.

Current Research and Potential Benefits of 3D-printed Artificial Muscles

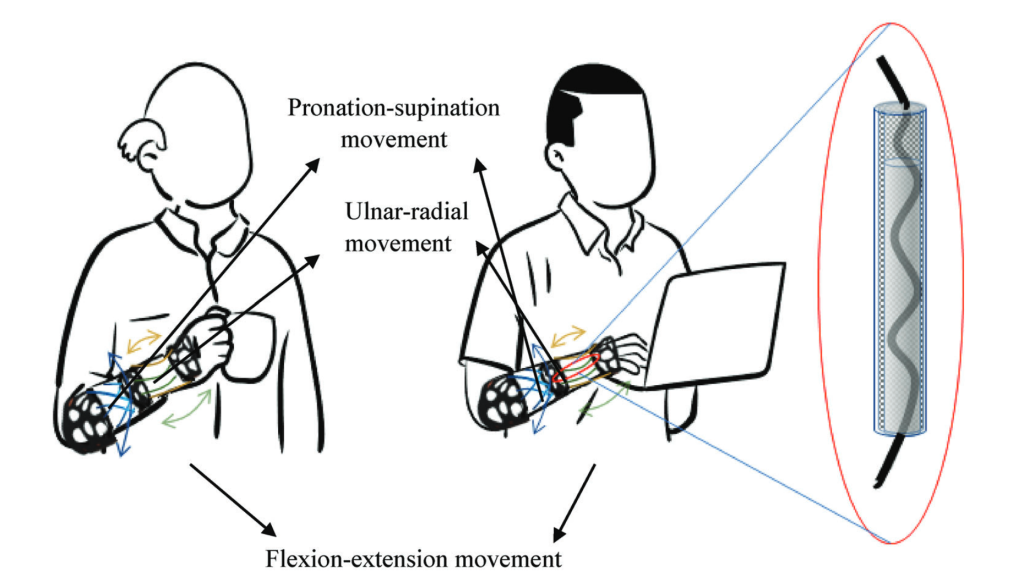

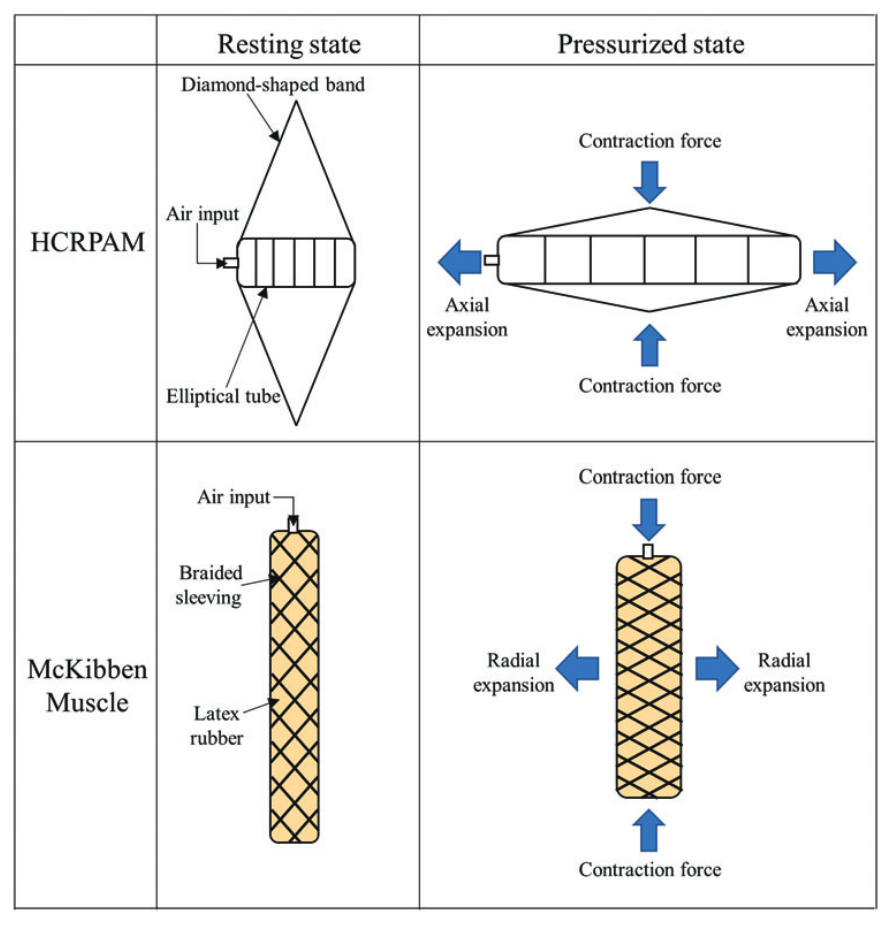

Recent breakthroughs in 3D printing technology are paving the way for innovative solutions in muscle repair and replacement, particularly for neurodegenerative diseases like ALS. As highlighted in a scientific paper by Mohammadi et al.(Figure 1.), researchers have demonstrated the potential of 3D-printed muscle structures that mimic the mechanical and functional properties of natural muscles. These artificial muscles are created from bio-compatible materials designed to integrate with existing tissues, offering a promising approach for either supporting weakened muscles or, in some cases, replacing damaged tissue entirely. Studies like those by Han et al.(Figure 2.)have further advanced this field by showcasing how 3D printing can achieve precise control over muscle architecture, enabling highly customized treatments.

Figure 1. Variable stiffness PTM(Phase Transition Muscles) glove to suppress tremors in forearm and hand. (Adapted from Adv. Mater. Technol. 2023, 8, 2300199)

Figure 2. Comparison of actuation concepts of HCRPAM and McKibben muscle. Radial expansion of McKibben muscle is limited by the braided sleeving. To obtain a high linear working distance, the HCRPAM expands in the axial direction. Color images available online at www .liebertpub.com/soro (Adapted from Soft Rob. 2017, 4, 249–255)

For ALS patients, this technology holds the promise of significantly improving quality of life. As muscle degeneration progresses in ALS, patients lose mobility and independence, but 3D-printed muscles could help restore some degree of movement and function. By providing structural support and facilitating motor activity, these printed muscles may offer a new avenue for rehabilitation and symptom management. While still in experimental stages, this technology could one day empower ALS patients with improved mobility, offering a more personalized and adaptable solution to meet each patient’s unique needs.

Moving Forward: Addressing Current Challenges

While the potential of 3D-printed muscles to revolutionize ALS treatment is incredibly exciting, several significant challenges remain. One of the biggest hurdles is ensuring that these artificial muscles function effectively and safely within the human body. For these muscles to be truly effective, they must integrate with the nervous system, allowing them to respond to brain signals and be controlled by the patient.

Although this technology is still in the experimental stages, researchers are optimistic. Progress is being made, and as innovation continues, there’s hope that 3D-printed muscles will one day offer ALS patients new options for restoring mobility and improving quality of life.