For most people in the United States who need an organ transplant, they will need to wait an average of three to five years on a list before they can get a lifesaving surgery. On average, 20 people die daily waiting on this list. There is a possibility of being able to bypass the wait time by manufacturing the required organs with 3D printing. This manufacturing technique was first used in the medical field for prosthetics and surgery practice models, with a goal to create fully functioning organs for those in need. Instead of using plastic or printer ink, the 3D printer uses cells to create biological constructions.

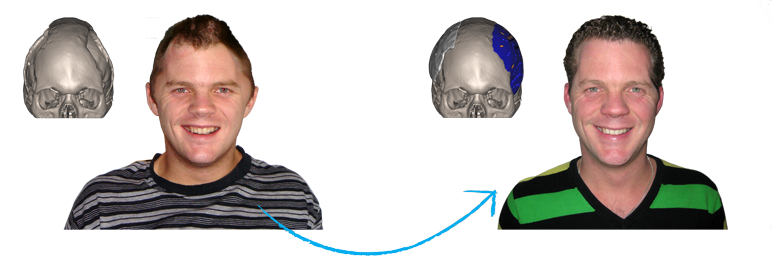

Traditional methods of artificial tissue and organ creation involve the use of stem cells, which are cells that do not have a designated purpose yet, to create a scaffold or frame for the organ. If cells for a desired organ are placed on the appropriate scaffold, they could multiply and grow into an artificial organ over time. If 3D printing is implemented using the same scaffold procedure, cells could be placed more precisely; the cell diameter can be better controlled, and the speed of the process can be controlled digitally. All of these aspects allow for better replication of the complex networks and structures found within biological tissues. A major advantage of the 3D printed organs are the customizations and variability that can be implemented with the method. Implants can be made to different sizes to suit each unique individual. If the original cells used for 3D printer material are from the intended recipient, the compatibility of the implant or artificial organ is nearly guaranteed. The risk of organ rejection is always present in the time following a transplant operation.

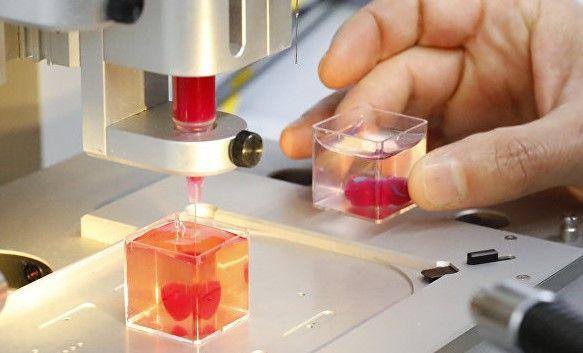

The 3D printing process is near perfect for certain medical uses, such as prosthetics, and dental implants, but more work needs to be done with the printing of tissues and organs. Small simple organs with thin walls can be done but printing larger organs such as hearts and kidneys requires integration of the vascular network, which cannot be done at this time. As printers become more precise and able to use a higher variety of cells, the creation of these vascular networks becomes more and more plausible.

Scientists are currently investigating a new way to print these complex organs by combining organic material with mechanical chips. These chips are able to replicate certain biological stimuli, including fluid flow and chemical gradients, in order to achieve some degree of organ function within a much simpler biological structure. Using these chips will allow for better mass production of a variety of tissues and organs. This particular technology is being used to create tissues that will be used for testing pharmaceutical drugs. There is an opportunity for these tissues to be expanded to use in the human body, but the majority of companies using this technology are still in the startup phase.

While the use of 3D printing to create complex artificial organs is not completely viable today, the technology is improving rapidly. Within a few years, the waiting times and problems with organ transplants could be a thing of the past.

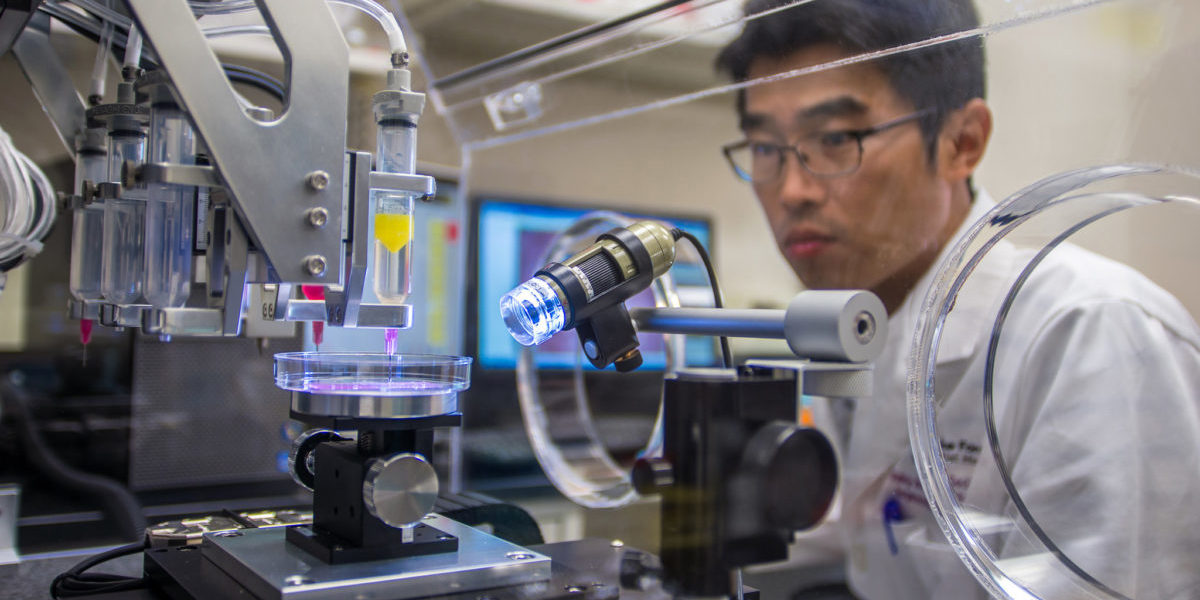

Featured image cropped from “3dPrinting scientist” by U.S. Army Materiel Command which is licensed under CC BY 2.0.