While regenerative medicine may not be time travel, recent research advances have given hope for using scaffolds as a potential treatment for osteoarthritis, a common form of arthritis.

Scaffolds for Cartilage Regeneration

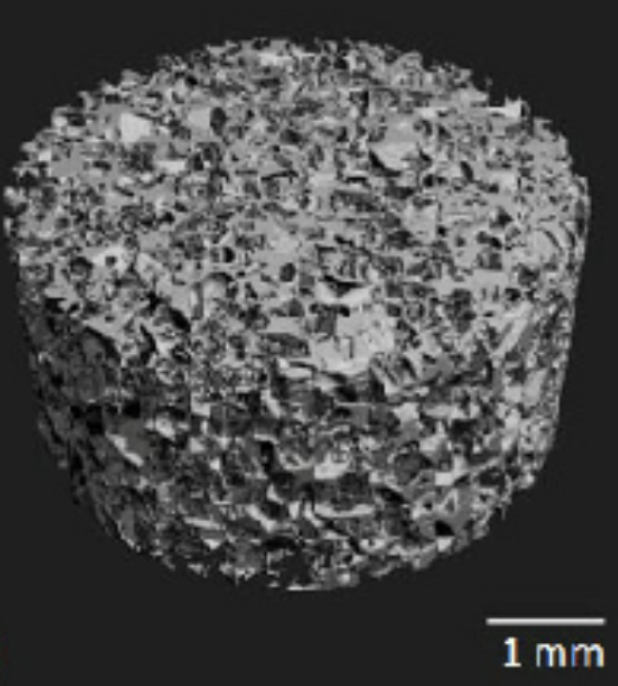

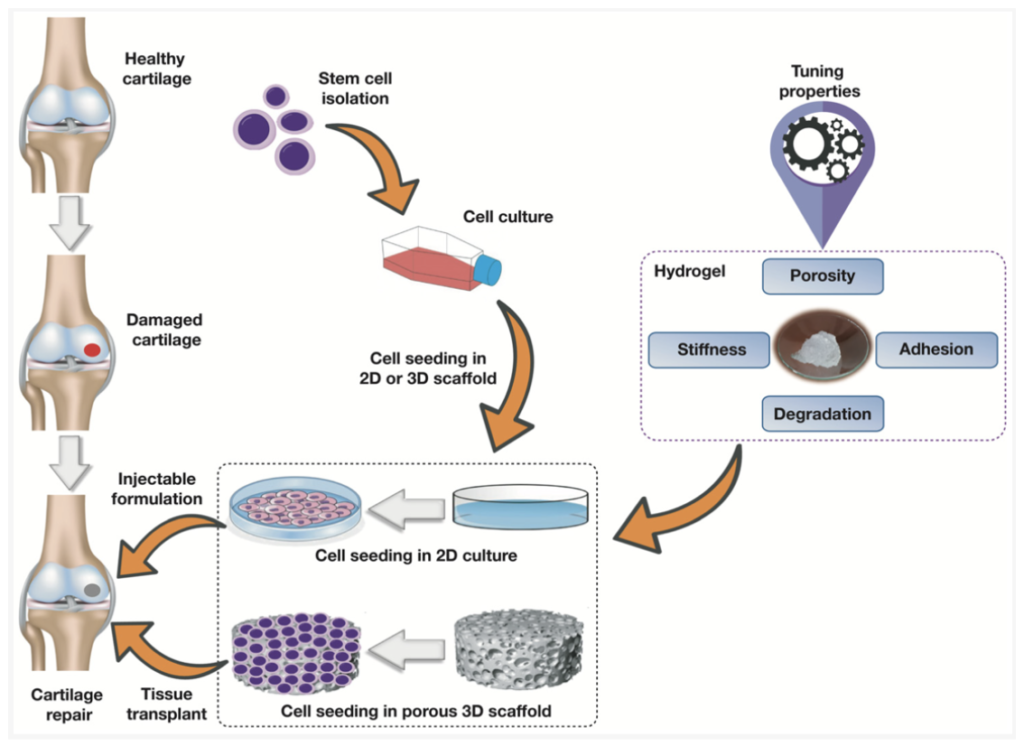

3-dimensional structures called scaffolds can be designed to foster the growth of cartilage in areas where it has worn down, such as the areas within the body suffering from arthritis. These scaffolds are designed to imitate the natural properties of human cartilage, most importantly, the stiffness. Additionally, in order for new cartilage to be able to grow within these scaffolds, pores are incorporated to allow for necessary nutrients to flow and growth to occur. The ability for water to flow through the scaffold, or the permeability, is a mechanical property utilized as a way to measure the potential nutrient flow through and cartilage ingrowth into the scaffold. Research on the manufacturing processes of these scaffolds provides information on how to achieve the necessary stiffness and permeability of the scaffold so that it is as similar as possible to that of natural cartilage.

Making the Scaffolds

Multiple techniques for making scaffolds are considered: Freeze-Extraction Porogen Leaching and 3D Fiber Deposition. For both of these methods, mechanical testing was conducted to conclude what design parameters affect the properties of the scaffold. There exists a correlation between the stiffness of the scaffold and the porosity; that is, a greater porosity corresponds to a less stiff scaffold. Freeze Extraction Porogen Leaching consists of mixing the scaffold material with a porogen material and freezing the mixture to create a distribution of pores after the porogen is removed. A higher porosity, and consequently higher permeability but lower stiffness, can be achieved by increasing the content of the porogen.

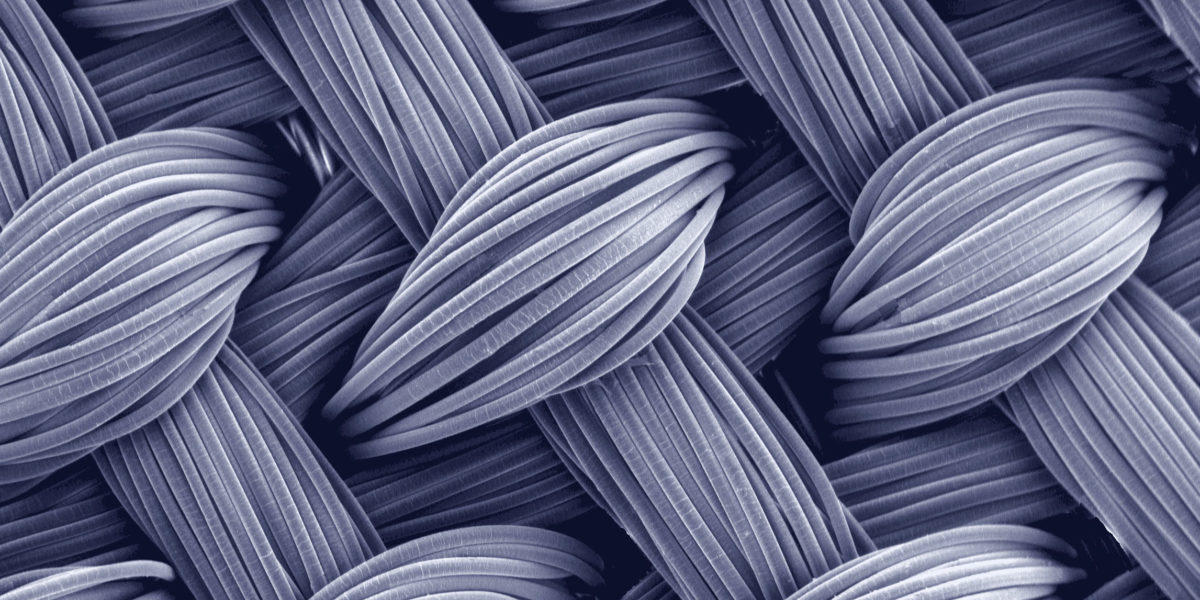

3D Fiber Deposition is an additive manufacturing process similar to 3-D printing which extrudes the scaffold layer-by-layer according to a predesigned model which allows for the distribution, size, and amount of pores to be explicitly defined. Various parameters of this process can be changed to produce different scaffolds. Increasing the size or amount of pores increases the permeability but decreases the stiffness of the scaffold, similarly to Freeze Extraction Porogen Leaching. Additionally, the thickness of each layer, orientation of each new layer relative to the previous layer, and size of the fiber being extruded can be altered to achieve the same trends in porosity.

Implementing the Scaffolds

So how exactly are these scaffolds used to turn back the clock on cartilage deterioration? Scaffolds can be seeded with stem cells and inserted into the area of the body where cartilage has worn down. Finite Element Analysis has modeled the insertion of a scaffold into a defected area, proving the effectiveness of the scaffold at regenerating cartilage when the properties of the natural cartilage are achieved by the scaffold. Cartilage stiffness varies depending on the location within the body, suggesting the importance of being able to tailor these scaffolds to have varying properties and motivating the study of trends between design parameters and material properties.

Featured image cropped and scaled from Scaffold for Growing Cartilage by NIAMS NIH licensed under CC BY-NC-SA 2.0.