Scientists are starting to grow meat the way farmers grow fruits. For thousands of years, people have raised animals for protein, but animal farming uses huge amounts of land and water and raises ethical questions about slaughter. To address these problems, researchers came up with a new idea: cultivated meat, which means growing muscle or fat cells from an animal until they form mature tissue.

Continue reading “Steaks and Strains: Biomechanics in Cultivated Meat”Tag: tissue engineering

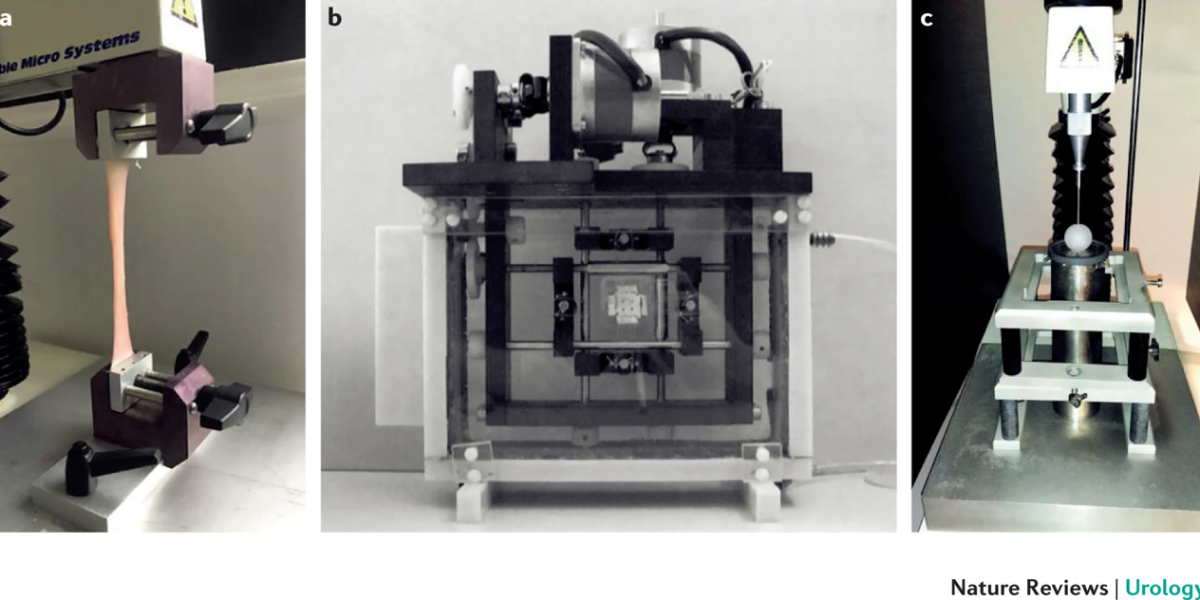

Engineering Hope: Advancing Bladder Biomechanics for Life-Changing Solutions

In a quiet hospital room, a young girl sat by her father’s bedside, watching him shift uncomfortably, tethered to a catheter that had become both a necessity and a burden. Her father, once active and independent, had been struggling with spinal cord injury for years. The catheter, while helping him manage his bladder, came with its own set of complications. For people like her father, or those with neurogenic bladder disorder, intractable incontinence, or even bladder cancer, the loss of bladder function can feel like a never-ending cycle of discomfort and distress. Relying on catheters, while necessary, often leads to Catheter Associated Urinary Tract Infections (CAUTI), further worsening their condition and even accelerating disease progression.1

New Hope for Pelvic Floor Health: Models and Scaffolds

About 30% of women worldwide experience Pelvic Floor Dysfunction (PFD), the failure of the pelvic floor muscles. PFD is often caused by childbirth and pregnancy, and it significantly impacts the quality of life for many women, highlighting the need for scientific solutions.

Continue reading “New Hope for Pelvic Floor Health: Models and Scaffolds”Chopsticks and Simulations: How this combination can save millions and years in cancer research

Did you know that getting a single drug approved can take around 20 years and cost millions of dollars? This lengthy process includes rigorous in vitro (lab-based), in vivo (animal testing), and clinical trials to ensure safety and efficacy.

But what if I told you that scientists are working on advanced 3D in vitro cell culture models that could bridge the gap between traditional 2D cell cultures and animal testing? These innovative models can potentially revolutionize drug development, saving both time and money.

Continue reading “Chopsticks and Simulations: How this combination can save millions and years in cancer research”Technology Saving Lives with 3D Bioprinting Organs and Tissues

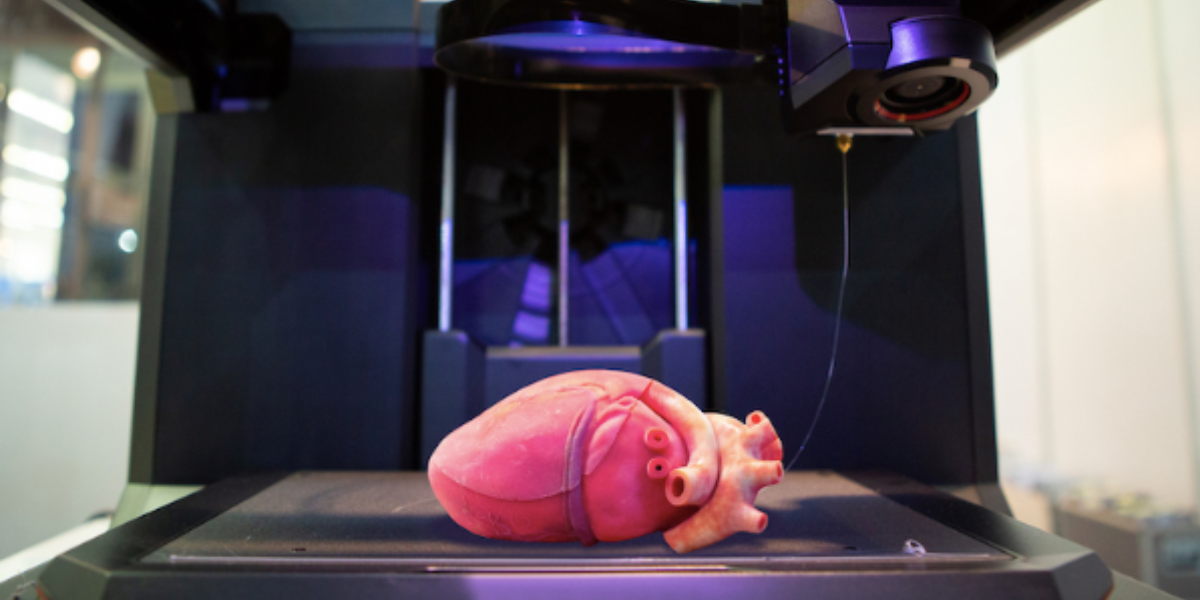

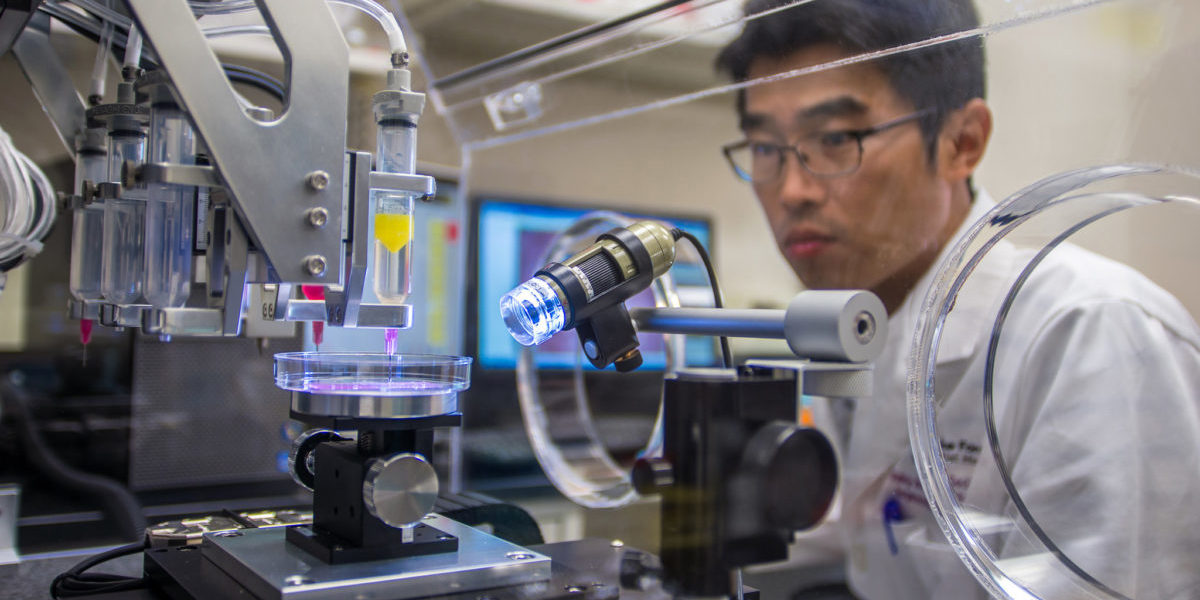

When you walk into the DMV and get your license for the first time, you get asked an important question. Would you like to be an organ donor? Many people are unsure how to respond at first because they don’t understand what it entails; however, by diving deeper, one can truly understand the impact of this decision. According to the Health Resources and Services Administration, 17 people die each day waiting for an organ transplant. The amount of donations received per day is not enough to outweigh the need for the transplant, and lives are lost every day. However, with new technology and medicine, the world of 3D printing organs, biocompatible materials, and tissues has made tremendous strides in saving lives.

In this blog article, I would like to discuss three aspects of bioprinting organs: the various materials, the different types of printing, and the internal bodily reactions.

3D bioprinting tissues is a very complex matter, starting with the topic of materials. The first thing to consider when 3D printing tissues is the material with which the patients specific product will be constructed. This is a challenge as the compatibility of the material needs to work with the printing machine and the patient’s body. The most common materials used are categorized into two separate types. The first type is natural polymers like gelatin and collagen, and the second is synthetic polymers like polyurethane. Ph.D. student Saeedeh Vanaei explains in a review paper that natural polymers are advantageous because they have low solubility levels and are very vicious. Natural polymers produce fewer issues during production, leading to fewer patient complications. On the other hand, synthetic polymers are advantageous because they have high tensile strength and can break down into smaller parts.

There are many different types of 3D printing of these biological organs. However, the most used include extrusion-based models, laser-assisted models, and bio inkjet droplet-based. In this field of bioprinting tissues and organs, bioinks is a term used to describe these previously mentioned polymers used to make artificial organs/tissues. A study by Tao Xu at the University of Clemson found that bioprinting using inkjet is a viable option for reproducing living tissues in animals. This type of engineering will be duplicated in human tissues.

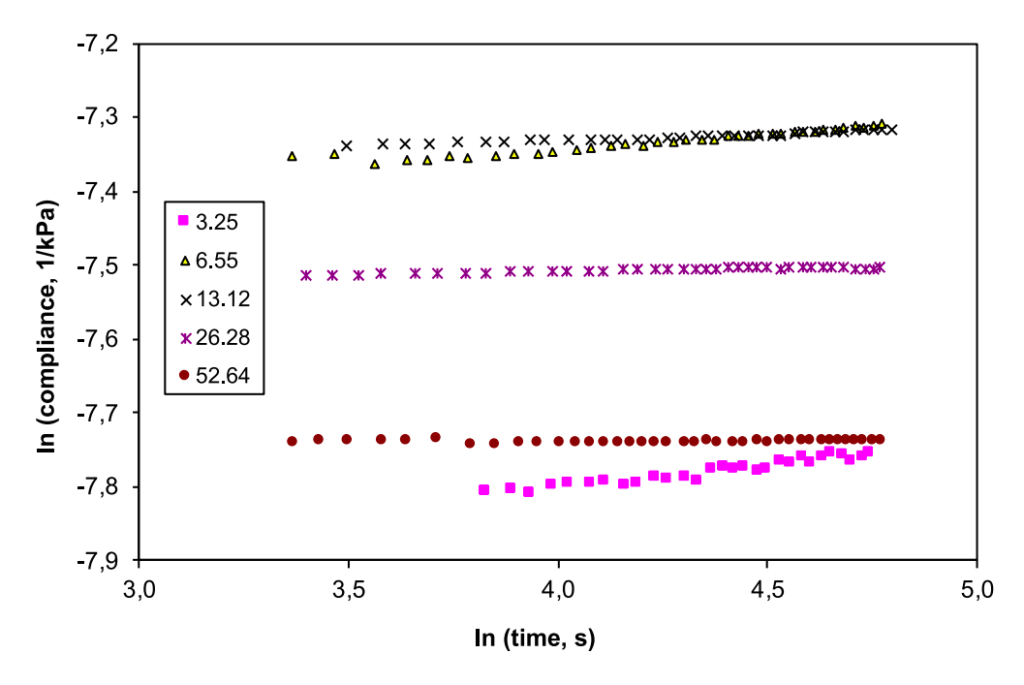

When a foreign intruder enters unknown territory, it is hard to determine the outcome. The same goes for the human body. It is almost impossible to match original tissues to 3D printed ones, and deadly complications can arise if the body doesn’t accept the foreign tissue. In their published study, Alexandra Zühlke and Michael Gasik performed creep tests that indicated the creep compliance of silicone bioprinted tissues. A creep test showes the changes and modifications a material undergoes when introduced to stresses. These tissues were placed under different stresses at various pressures. Their creep compliance can be seen in the figure to the left. The results concluded pressures that the foreign tissue would need to exert on the neighboring parts of the body to lead to the least amount of complications. These complications can lead to surrounding tissue dying and could likely result in the need to remove the bioprinted organ surgically.

Overall, considering the very high organ demand, 3D bioprinting these tissues gives hope and security to patients worldwide. For more information on this topic of the advancements of the technology 3D printing organ, please visit these two articles here and here.

This Toner Might Be More Expensive: 3-D Printing Artificial Organs

For most people in the United States who need an organ transplant, they will need to wait an average of three to five years on a list before they can get a lifesaving surgery. On average, 20 people die daily waiting on this list. There is a possibility of being able to bypass the wait time by manufacturing the required organs with 3D printing. This manufacturing technique was first used in the medical field for prosthetics and surgery practice models, with a goal to create fully functioning organs for those in need. Instead of using plastic or printer ink, the 3D printer uses cells to create biological constructions.

Continue reading “This Toner Might Be More Expensive: 3-D Printing Artificial Organs”Can we 3D print our own skin?

Can you imagine a world where amputees receive replacement limbs which are able to detect temperature and pressure like an actual limb? How about a world where when you get a cut, you can 3D print some of your own skin to patch the wound?

Continue reading “Can we 3D print our own skin?”